Shielding

An expertise for your shielded room

Our know-how allows us to offer you high-performance shielded room adapted to EMC, antenna measurements and data protection.

Indeed, the shielding performances of our installations meets the requirements of the French, European and international current standards.

Our offer covers several types of faradisation: modular self-supporting structures, welded copper foil and modular welded steel, with a minimum efficiency of 120 dB over a frequency range of 10 kHz to 40 GHz.

We adapt the installation to the customer’s building constraints, so our custom-made shielded rooms are installed in both new and existing buildings.

We also supply the faradisation elements that make up the shielded room. These include the doors and all the passageways. They are designed to guarantee the electromagnetic attenuation performance.

We have produced installations of all sizes, from a few dozen centimetres up to a hundred metres long.

Our modular shielded rooms assembled by profiles

Our self-supporting modular shielded rooms are made of composite panels covered with galvanised steel sheets. The assembly is carried out by steel profiles and self-tapping screws. The assembly has no gasket, bolts or inserts, which ensures that it can be disassembled and reassembled without any deterioration of performance. This assembly principle therefore requires no maintenance.

Our modular shielded rooms in welded steel

Our self-supporting modular shielded rooms are made of welded steel sheets. The assembly is done by welding. The modules are manufactured in the workshop and assembled on site. This type of shielded room is particularly sought-after for the protection of command/control centres against High Altitude ElectroMagnetic Pulses (HA-EMP).

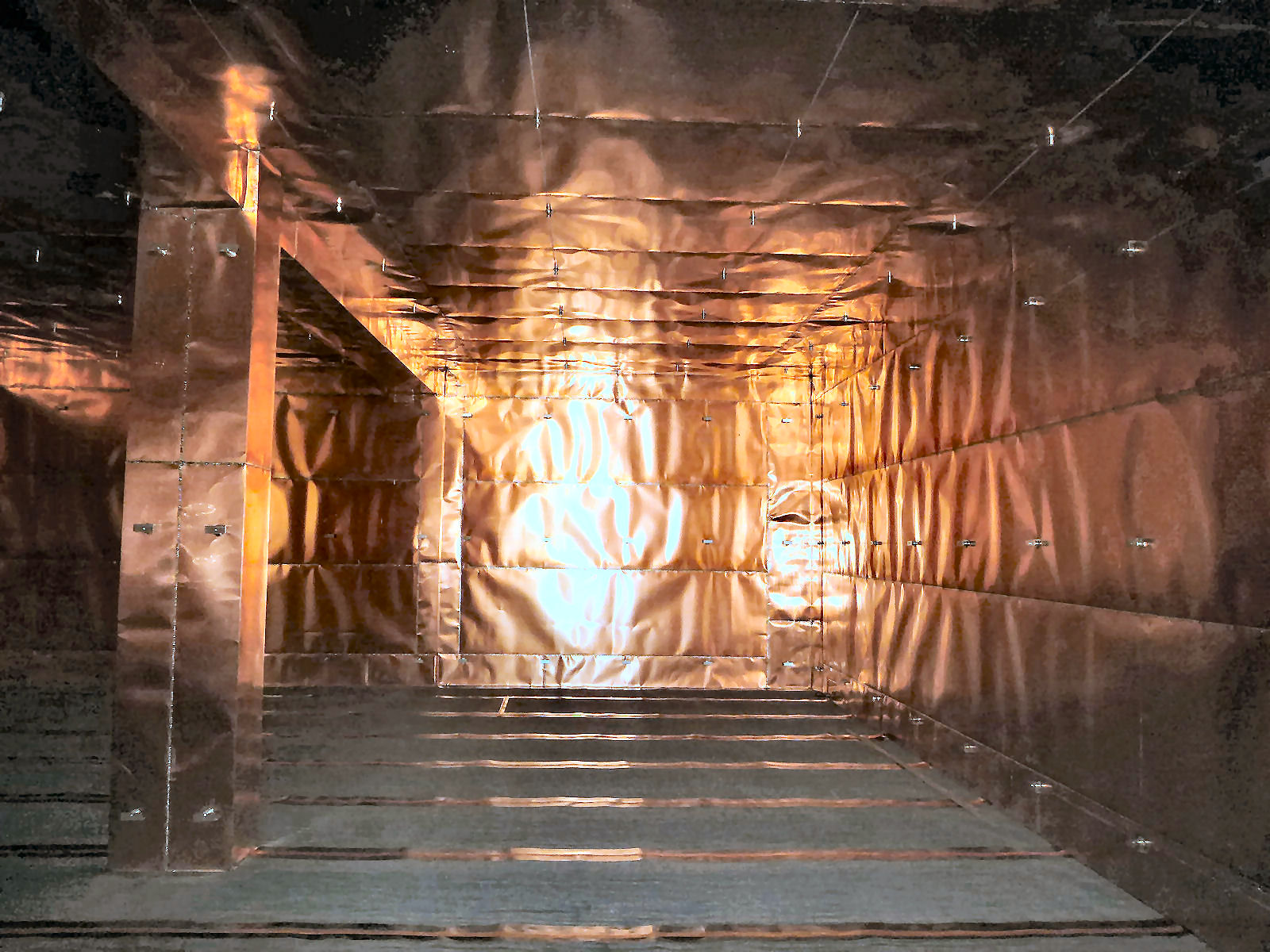

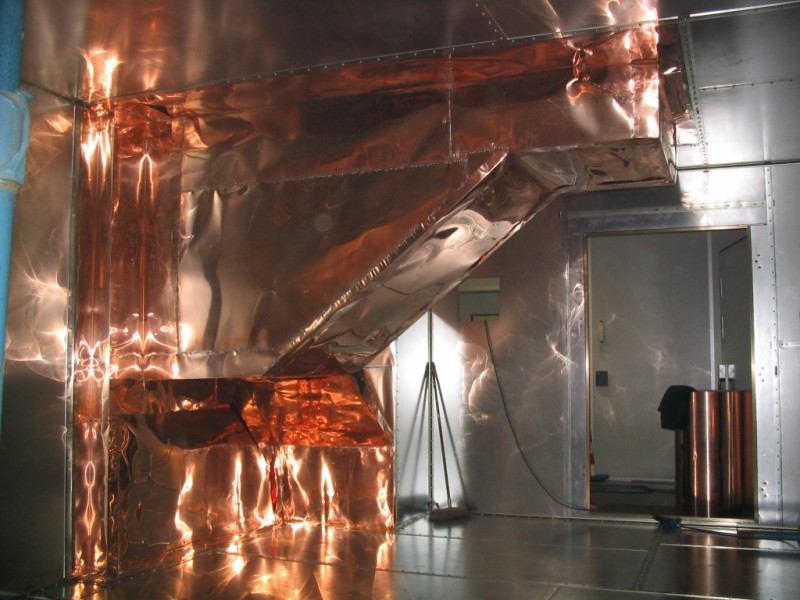

Our welded copper shielded rooms

We manufacture Faraday cages made of copper foil. The installation is laid directly on the walls of the installation room. This technology allows us to cover the entire volume of the room and to take into account particular geometries: posts, beams, curves, excavations, pits, etc.

The advantages of our Faraday cages

- Excellent ageing and corrosion resistance;

- High, measurable and guaranteed performance;

- Tailor-made and adapted to any requirement in terms of size or geometry of the installation room (new or existing);

- Scalability of the faradisation: modifications, transfers, adaptations can easily be made;

- Benefit from 35 years of experience;

- Advice and support from our design office throughout your project;

- Maintenance service for all brands;

- Siepel Measurements, accredited ISO 17025, carries out performance measurements of all types of

- Faraday cage and anechoic chamber.